[ HATEBUR ] Saving potential with the servohydraulic ejector module

페이지 정보

본문

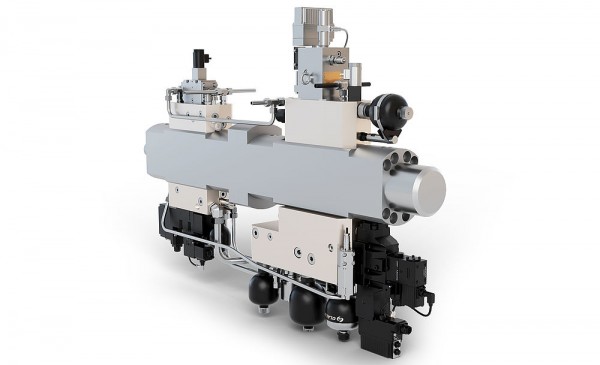

Hatebur recently developed a new servohydraulic ejector module and checked it extensively at a test station. After positive results from the test run, the module was installed on the HOTmatic AMP 30 and successfully tested under real production conditions at the test center in Reinach.

By using servohydraulic axles, the highly dynamic position, force and speed controls can be realized in the whole forging process. The movement of each individual module can be selected independently of the machine movement and so can be optimally designed to suit the process. For a tool change, the ejector stroke does not have to be manually adjusted like before. Instead, it can simply be entered on the machine’s touch screen. The ejector module has an integrated pressure and position measuring system, with which the ejector movement can be exactly determined together with the ejector force.

One of the new functions of the module is descaling/in‑die forming. This combination makes it possible to handle two process steps in one stage. In the first step, the scale in front of the die is removed during a compressing process. Thanks to the controllable oil flow in the ejector cylinder, the cut‑off is descaled before the die and inserted into the die in which it is pressed into the required form. This process combination of descaling outside the die, which is comparable to a conventional descaling station, means that Hatebur HOTmatic operators benefit from a longer tool service life as well as fewer machining allowances on the forging.

An important topic nowadays is raw material saving. In order to meet expectations in this regard, the Hatebur development team uses a “slim slug process”. A reduced slug thick‑ness is achieved thanks to a modified position when forming between the ejector and the punch. When the corresponding position is reached, the ejector moves to the required height of the finished part and the forging is pressed into its final shape. Depending on the configuration of the rings, the slug thick‑ness can even be reduced to almost half its original thickness. The tool service lives are comparable with the process today, thereby not resulting in any more downtime for the HOTmatic production system. For example, this slim slug process can save around 25 grams of raw material with a combination ring 6008 blank. This generates an incredible saving of 250 tons for an annual volume of 10 million parts.

The piercing/separating procedure and separation of the rings results in a considerable increase in process reliability with the ejector module. Thanks to the adjustable movement of the module, accurate pierce positioning is no problem for the cylinder’s position measurement system. The easily adjustable starting position of the ejector allows the inner ring to be ejected in a slow, gentle way without impact because the return stroke is eliminated. Furthermore, the function enables both rings in the machine to be brought out separately and the loads to be monitored. With this new ejector system, old systems such as water cushions or piercing/separating curves can be replaced. This leads to a simpler construction in the tool, which in turn lowers tool costs.

- 이전글[ IMANPACK ] Dosing and packaging system for religious medals 23.05.25

- 다음글[ AGATHON standard parts] 새로운 이름 "Precision-Parts " 23.01.19

댓글목록

등록된 댓글이 없습니다.