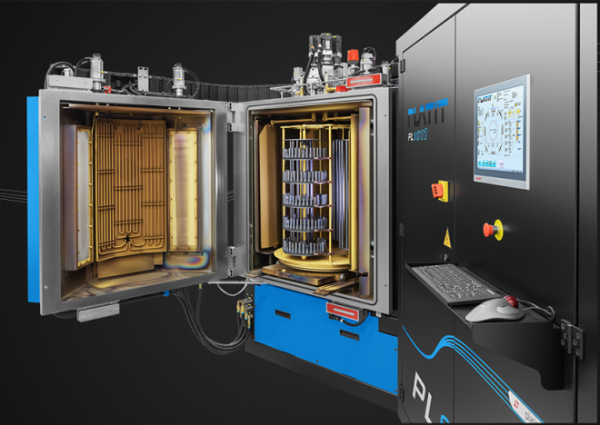

[PLATIT] 스위스 코팅 장비 PL1011

페이지 정보

본문

The PL1011 is the backbone of every high-volume coating center. It has four Planar cathodes utilizing ARC technology and allows for the deposition of all PLATIT standard coatings at a consistently high level of quality and productivity. This coating unit combines maximum production availability with a user-friendly interface and maintenance concept.

The PL1011 is designed for customers who seek a mix of process reliability and high-quality coatings at a low cost per tool.

TECHNOLOGIES APPLIED:

- 4 x Planar cathode using ARC technology for depositing

ETCHING TECHNOLOGIES APPLIED:

- LGD® (Lateral Glow Discharge)

- Plasma etching with argon, glow discharge

- Metal ion etching (Ti, Cr)

LOAD AND CYCLE TIMES:

- Max. coating volume [mm]: ø715 x H805

- Max. coating height with defined coating thickness: 711mm

- Max. load: 400kg

- 3 batches/day

MODULAR CAROUSEL SYSTEMS:

- 1 to 12 axes

SOFTWARE:

- Simple use and maintenance

- PLATIT’s SmartSoftware (PC and PLC system)

- Modern control system with touch screen

- Data recording and real-time display of process parameters and flow

- Manual and automatic process control

- Remote diagnostics and maintenance

MACHINE DIMENSIONS:

- Footprint [mm]: W4000 x D2250 x H2350

- 이전글[Motorex] WELCOME TO THE MOTOREX AROUND THE WORLD PHOTO CHALLENGE! 21.08.25

- 다음글[IMANPACK] 이태리 Palletizing and Handling machines 21.08.19

댓글목록

등록된 댓글이 없습니다.